Milling & Separation systems

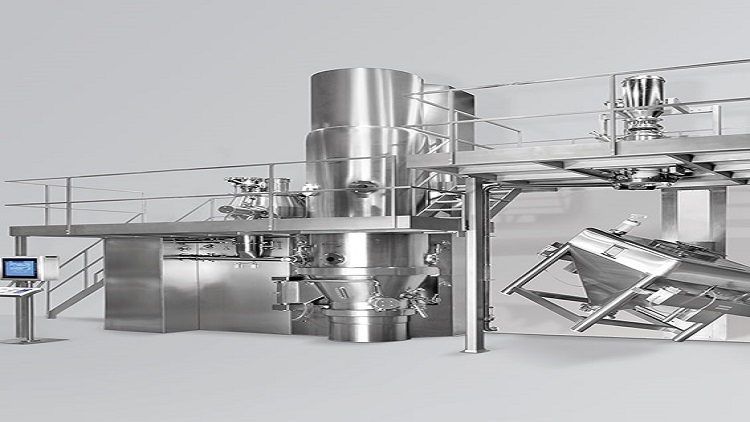

The granulation line CCS made by DIOSNA is an efficient production plant consisting of a mixer granulator and a fluid bed processor. The two parts of the line are directly connected to each other and provide best production results on the basis of their optimum adaptation. The completely closed product transfer is the ideal precondition for container applications. The control via two control terminals facilitate handling of the plant for the operating and maintenance personnel. Because the two parts of the line can also be operated independently from each other, they remain flexible in their applications. In the CGS design (Compact Granulation System), additional advantages like low space requirements, increased productivity and yield of product

- Perfectly adapted plants

- Low material loss thanks closed product transfer

- Through-the-wall concept for strict separation of production and technical area

- Automated processes and short set-up times

- Common operating interface for all plants

- Pressure-surge-resistant design up to 12 bar of the fluid bed process

- Fast product transfer

- Optimised yield of product thanks reduced surfaces with product contact

- Decoupling for explosion prevention is not necessary

- Optimum accessibility of all components by means of an operator platform

- No lifting column required

- Pressure-surge-resistant design up to 12 bar for the mixer granulator

- Top spray-/ tang-spray -/ Wurster processes in the fluid bed

- Containment design for highly active substances

- Comprehensive component program for handling and product preparation

- Qualification performance compatible with pharmaceutical guidelines

| Unit | Size | |

|---|---|---|

| Typical batch sizes | kg | 5-56 |

| Dimensions (WxDxH) | mm | 1250 x 1250 x 1950 |

| Unit | Size | |

|---|---|---|

| Typical batch sizes | kg | 5-56 |

| Dimensions (WxDxH) | mm | 1250 x 1250 x 1950 |

| Unit | Size | |

|---|---|---|

| Typical batch sizes | kg | 5-56 |

| Dimensions (WxDxH) | mm | 1250 x 1250 x 1950 |

| Unit | Size | |

|---|---|---|

| Typical batch sizes | kg | 5-56 |

| Dimensions (WxDxH) | mm | 1250 x 1250 x 1950 |

| Unit | Size | |

|---|---|---|

| Typical batch sizes | kg | 5-56 |

| Dimensions (WxDxH) | mm | 1250 x 1250 x 1950 |

| Unit | Size | |

|---|---|---|

| Typical batch sizes | kg | 5-56 |

| Dimensions (WxDxH) | mm | 1250 x 1250 x 1950 |