Duct Washing System For Fbd And Tablet

GENESIS PROCESS TECHNOLOGIES was established with a vision to become a quality supplier and soluon provider for process machineries catering to Pharmaceucal, Nutraceucal, Food and Chemical industry. In our wide range from the smallest lab scale units to large producon units required for Granulaon, Drying, Milling & Blending; we ensure high quality standards for products and services.

Genesis is your reliable and competent partner for best technologies individually designed for your producon process to a team which has experience of more than 25 years in the pharma industry.

Inlet and outlet duct washing System is important in Pharma Industries to clean the duct and avoid the contamination from Batch to batch in single Vessel

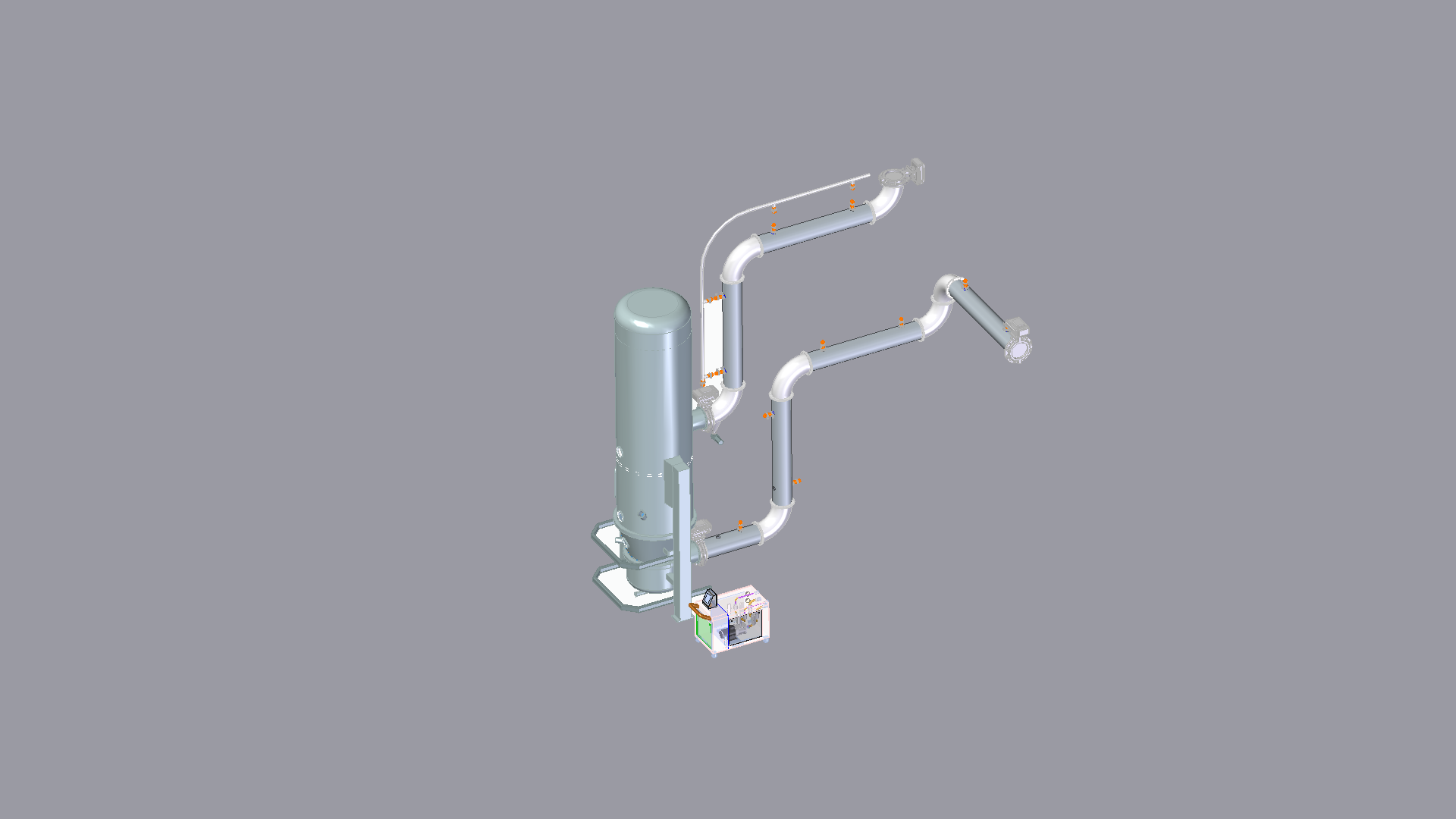

Duct wash system is designed by Designing special troll ball assembly fixed on duct at various locations considering the layout of machine, including bends and drain points.

A movable trolley having booster pump and pneumatic operated butterfly valves, fully automatic PLC/HMI controlled programmed to complete washing with given recipe.

A complete integrated system confirms the duct washing uniformly and consistently.

- Addressing important requirement of duct cleaning for Pharma grade equipment like FBD and Auto coaters

- Spray nozzle mechanism

- Customization as per plant layout

- HMI/PLC based automated cleaning protocol control possible

- Complete integrated system

- Ensures uniform and consistent duct washing

- FDA regulatory compliant

- Flush fitting adaptor welding on duct diameter

- Removable Tri-clover type troll ball assembly fixed against adaptor inside duct to ensure no-leakage

- “O-Ring” design ensure zero leakage and 12 bar explosion pressure testing

- Ultra sanitary, Low flow, Variable pressure tank washer

- Movable trolley with booster pump and automation control